They are mixtures of plastomeric polymers that are added directly in the mixer during the production (PMA technology – Polymer Modified Asphalt) to improve the physical-mechanical performances of asphalt concretes. Quality standards of the final product containing polymeric compounds are optimised, obtaining higher tensile strength and greater resistance to fatigue, rutting and thermal excursion.

(K-PLAST POLYMER – RUTTING RESISTANCE TO STATIC AND DYNAMIC LOADING AT HIGH TEMPERATURES)

Traditional bitumens and asphalt mixtures show temperature and time-dependent behaviour. Rutting or permanent deformation is therefore the leading cause of pavement deterioration in temperate and warm climatic regions of the world while low-temperature cracking is a common problem in cold regions.

K-PLAST is a polymeric compound of selected polymers made of flexible granules which, when added to the asphalt mix, increases the pavement strength, the fatigue resistance, the resistance to rutting and stripping and allows to obtain high resilient modulus.

The improved stiffness of K-PLAST asphalt and its reduced temperature susceptibility, make it an advantageous component of bituminous base and binder courses. The higher modulus reached by K-PLAST asphalt gives it an improved capacity to distribute loads.

This, in turn, will result in lower stresses on the unbound layers of the pavement and a lower tensile strain in the asphalt materials, resulting in a longer life for the road structure.

Rutting is a primary reason of premature deterioration of asphalt highway pavements. Pavements constructed with polymer and other modifiers are showing improved performance. When the virgin asphalt and modified HMA mixes used on several test sections worldwide are compared in field evaluation, the observation and results confirm the relatively poor performance of the virgin asphalt section with respect to rutting, compared to modified HMA sections.

The rutting problem is also associated with high pavement temperatures during the summer months. The high temperatures reduce the asphalt cement viscosity, which can make the mix susceptible to rutting.

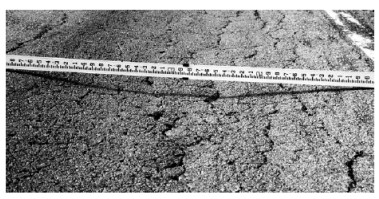

Rutting can be defined as a Surface depression in the wheel path. Pavement uplift (shearing) may occur along the sides of the rut. Ruts are particularly evident after a rain when they are filled with water. There are two basic types of rutting : mix rutting and subgrade rutting.